Corrosion Protection for Metal Connectors in Australia: An Engineer’s Perspective

August 11, 2025

Australia’s diverse climate zones - from coastal salt-laden air to arid inland deserts - demand a strategic approach to corrosion protection for metal connectors. Engineers must consider environmental exposure, material compatibility, and regulatory compliance to ensure structural integrity and longevity.

When a metal connector is used inside a dry building envelope the level of protection is clearly defined in AS1684, Residential timber-framing construction standard, specifies that a minimum corrosion protection of Z275 shall be provided.

For applications outside of the building envelope the National Construction Code (NCC) should be consulted in conjunction with other Standards like AS4312, Atmospheric corrosivity zones in Australia.

The NCC outlines corrosion protection requirements for metal connectors used in structural applications under:

- Volume Two – Housing Provisions:

- Part H1 Structure: Requires that materials exposed to environmental conditions must be durable and protected against corrosion.

AS 4312 defines corrosivity zones (C1 to CX), which guide the selection of protective coatings and materials.

| Zone | Description | Typical Environments | Corrosion Rate (Steel) |

|---|---|---|---|

| C1 | Very Low | Dry, climate-controlled interiors | < 1.3 µm/year |

| C2 | Low | Rural areas, low pollution, dry inland | 1.3–25 µm/year |

| C3 | Medium | Urban areas, light industrial, some coastal | 25–50 µm/year |

| C4 | High | Coastal, industrial with moderate pollution | 50–80 µm/year |

| C5 | Very High | Industrial with high humidity, aggressive coastal | 80–200 µm/year |

| CX | Extreme | Offshore, severe marine, tropical with salt spray | > 200 µm/year |

Corrosivity in Australia as defined in AS/NZS 2312.2 and described in AS 4312

| Category | Generic examples | Specific examples | |

|---|---|---|---|

| CX | Severe surf shore-line | Surf beach shoreline regions with very high salt deposition. | Some Newcastle beaches |

| C5 | Surf Sea-shore |

Within 200 m of rough seas & surf beaches. May be extended inland by prevailing winds & local conditions. |

More than 500 m from the coast in some areas of Newcastle |

| C4 | Calm Sea-shore |

From 200 m to 1 km inland in areas with rough seas & surf. May be extended inland by prevailing winds & local conditions. From the shoreline to 50 m inland around sheltered bays. In the immediate vicinity of calm salt water such as harbour foreshores. |

All coasts |

| C3 | Coastal |

From 1 km to 10 km inland along ocean front areas with breaking surf & significant salt spray. May be extended inland to 50 km by prevailing winds & local conditions. |

Metro areas of Perth, Wollongong, Sydney, Brisbane, Newcastle, & the Gold Coast |

| From 100 m to 3 – 6 km inland for a less sheltered bay or gulf. |

Adelaide & environs |

||

| From 50 m to 1 km inland around sheltered bays. |

Port Philip Bay & in urban & industrial areas with low pollution levels |

||

| C2 | Arid/Urban Inland |

Most areas of Australia at least 50 kilometres from the coast. |

Canberra, Ballarat, Toowoomba & Alice Springs |

| Inland 3 – 6 km for a less sheltered bay or gulf. |

Adelaide & environs |

||

|

Can extend to within 1 km from quiet, sheltered seas. |

Suburbs of Brisbane, Melbourne, Hobart |

||

| C1 | Dry indoors | Inside heated or air conditioned buildings with clean atmospheres. | Commercial buildings |

Reference: Galvanizers Association of Australia

AS 4312 provides a classification system for atmospheric environments based on their corrosive potential. Consideration should also be made on other factors affecting corrosion that include micro-climate impacts from pollutant and chemical attack and shelter from rain.

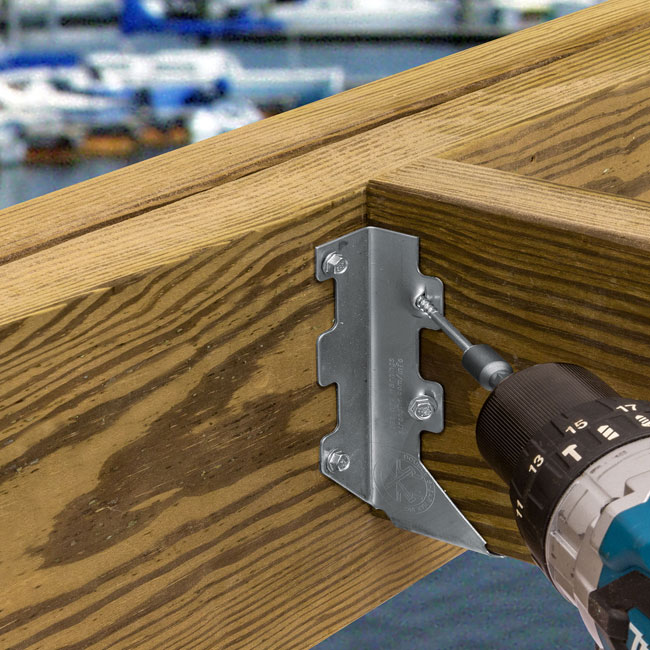

Simpson Strong-Tie provides corrosion guidance tailored to Australian conditions:

| Environment | Recommended Material/Coating |

|---|---|

| Low - Dry Internal (C1) |

Z275, Zinc-plated or mechanically galvanized steel |

| Medium - Wet External (C2-C3) |

ZMAX, Hot-dip galvanized (HDG) or Double-Barrier coating |

| Severe- Elevated/Industrial | HDG or 304/316 stainless steel |

| Marine/Coastal (C4-C5-CX) | 316 stainless steel or proprietary severe-duty coatings, FREP material (FREP Joist Hanger, FREP Joist Connector) |

| Uncertain/Unknown |

Default to 316 stainless steel or FREP material (FREP Joist Hanger, FREP Joist Connector) |

Key Notes:

Fastener Compatibility: Always match fastener material to connector material to avoid galvanic corrosion.

- Applying protective coating like primers and sealant may also provide additional durability.

- Preservative-Treated Timber: Use corrosion-resistant fasteners (e.g., stainless steel) with ACQ, CCA, or other aggressive treatments.

Corrosion protection in Australia is not one-size-fits-all. Engineers must align their material and coating choices with the NCC, AS 4312, AS/NZS 2312 and Simpson Strong-Tie’s guidance. By understanding the environmental exposure and applying the right protection strategy, we can ensure the longevity and safety of metal connectors across Australia’s diverse climates.

Structural Connections

Unmatched Quality from the Truss to the Foundation

With nearly 60 years of field and R&D experience, Simpson Strong-Tie® timber connectors are manufactured to the industry's highest standards. From framing angles to straps to heavy-duty joist hangers, we offer the most diverse product line so that you have the right product for the job.

Simpson Strong-Tie® connectors offer unmatched quality with laboratory and field testing, and are backed by our uncompromising commitment to customer service. As the company that built the connector industry, you can count on Simpson Strong-Tie® to work closely with builders, engineers and building officials to deliver innovative, building code-compliant solutions to help build safer, stronger structures economically. Download the Structural Connectors Overview Flyer.

Timber Connectors

From testing to service to availability, everything we do is engineered to ensure your project's success. With every product, you know you are getting the quality, value, service and on-time delivery that we have built our reputation on for the past 60 years.

From straps and ties to joist hangers and much more, Simpson Strong-Tie® structural connectors increase the strength and safety of timber-frame structures. Each connector is unique to Simpson Strong-Tie and is designed for specific applications without the need to adapt metal plating to suit a connection.

Steel Frame Connectors

From fully tested and engineered connectors and clips Simpson Strong-Tie® provides comprehensive structural solutions for cold-formed steel construction. From steel-to-steel connections to full-scale lateral solutions and curtain wall connectors, we remain committed to developing new technology that helps to advance the cold-formed steel industry.

Find out how Simpson Strong-Tie timber connectors can help you build the right way every day. Download the Cold-Fromed Steel Construction Connectors Catalogue.