General Corrosion Information

Understanding the Corrosion Issue

Metal connectors, fasteners and anchors can corrode and lose carrying capacity when installed in corrosive environments or when installed in contact with corrosive materials. The many variables present in a building environment make it impossible to predict accurately whether, or when, corrosion will begin to reach a critical level. This relative uncertainty makes it crucial that specifiers and users be knowledgeable about the potential risks and select a product suitable for the intended use. When there is any uncertainty about the possible corrosion risks of any installation, a qualified professional should be consulted. Because of the risks posed by corrosion, periodic inspections should be performed by a qualified engineer or qualified inspector and maintenance performed accordingly.

It’s common to see some corrosion in outdoor applications. Even stainless steel can corrode. The presence of some corrosion does not mean that load capacity has been affected or that failure is imminent. If significant corrosion is apparent or suspected, then the wood, fasteners, anchors, and connectors should be inspected by a qualified engineer or qualified inspector. Replacement of affected components may be appropriate.

Because of the many variables involved, Simpson Strong-Tie cannot provide estimates of the service life of connectors, anchors, and fasteners. We suggest that all users and specifiers obtain recommendations on corrosion from the suppliers of the materials that will be used with Simpson Strong-Tie products, in particular, treated wood or concrete. We have attempted to provide basic knowledge on the subject here, and have additional information in our technical bulletins on the topic (Product Use Information).

Corrosion Resistant Products

Corrosion Conditions

Corrosion can result from many combinations of environmental conditions, materials, construction design, and other factors, and no single guideline addresses all corrosion possibilities. Nevertheless, important corrosion information can be obtained from the American Wood Protection Association (AWPA), the International Building Code (IBC), International Residential Code (IRC), and local building codes. The following discussion provides general guidelines and approaches for the selection of Simpson Strong-Tie products for various construction conditions, but is not intended to supersede the guidelines of the AWPA, IBC, IRC, or local building codes.

Corrosion issues for Simpson Strong-Tie products generally fall into four categories:

1. Environmental and Construction Factors

Many environments and materials can cause corrosion, including ocean salt air, condensation, duration of wetness, fire retardants, fumes, fertilizers, chlorides, sulfates, preservative-treated wood, de-icing salts, dissimilar metals, soils, and more. Designers must take all of these factors into account when deciding which Simpson Strong-Tie products to use with which corrosion-resistant coatings or materials.

The design, quality of construction, and misinstallation can directly affect the corrosion resistance of products. A product intended and installed for use in dry-service environment may corrode if the structure design or building materials allow moisture intrusion, or expose the product to corrosive conditions, such as moisture or chemicals contained in the construction materials, soils, or atmospheres.

2. Chemically Treated Lumber

Some wood-preservative or fire-retardant chemicals or chemical retention levels create increased risk of corrosion and are corrosive to steel connectors and fasteners. For example, testing by Simpson Strong-Tie has shown that ACQ-Type D is more corrosive than Copper Azole, Micronized Copper Azole, or CCA-C. At the same time, other tests have shown that inorganic boron treatment chemicals, specifically SBX-DOT, are less corrosive than CCA-C.

Because different chemical treatments of wood have different corrosion effects, it’s important to understand the relationship between the wood treatment chemicals and the coatings and base metals of Simpson Strong-Tie products.

The preservative-treated timber supplier should provide all of the pertinent information about the treated wood product. The information should include the AWPA Use Category Designation, wood species group, wood treatment chemical, and chemical retention. See building code requirements and appropriate evaluation reports for corrosion effects of wood treatment chemicals and for fastener corrosion resistance recommendations.

With Fire-Retardant-Treated (FRT) Wood, the 2015 and 2018 IBC Section 2304.10.5.4 and 2015 and 2018 IRC Section R317.3.4 refer to the manufacturers’ recommendations for fastener corrosion requirements. In the absence of recommendations from the FRT manufacturer, the building codes require fasteners to be hot-dip galvanized, stainless steel, silicon bronze or copper. Simpson Strong-Tie further requires that the fastener is compatible with the metal connector hardware. Fastener shear and withdrawal allowable loads may be reduced in FRT lumber. Refer to the FRT manufacturer’s evaluation report for potential reduction factors.

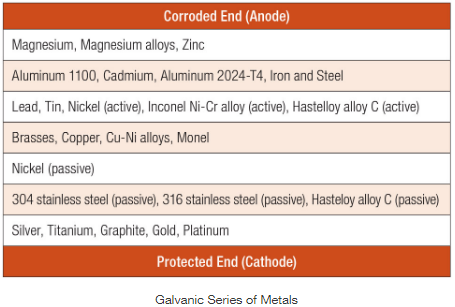

3. Dissimilar Metals and Galvanic Corrosion

Galvanic corrosion occurs when two electrochemically dissimilar metals contact each other in the presence of an electrolyte (such as water) that acts as a conductive path for metal ions to move from the more anodic to the more cathodic metal. Good detailing practice, including the following, can help reduce the possibility of galvanic corrosion of fasteners and connectors:

Galvanic corrosion occurs when two electrochemically dissimilar metals contact each other in the presence of an electrolyte (such as water) that acts as a conductive path for metal ions to move from the more anodic to the more cathodic metal. Good detailing practice, including the following, can help reduce the possibility of galvanic corrosion of fasteners and connectors:

- Use fasteners or anchors and connectors with similar electrochemical properties

- Use insulating materials to separate dissimilar metals

- Ensure that the fastener or anchor is the cathode when dissimilar connector metals are present

- Prevent exposure to and pooling of electrolytes

If you are uncertain about the galvanic corrosion potential of any installation, always consult with a corrosion expert. See the product pages for particular parts for more information regarding what coating systems are recommended or required for use with the parts in question.

4. Hydrogen-Assisted Stress-Corrosion Cracking

Some hardened fasteners may experience premature failure from hydrogen-assisted stress-corrosion cracking if exposed to moisture. These fasteners are recommended for use only in dry-service conditions.

Corrosion and Product Use

Simpson Strong-Tie connectors, anchors and fasteners feature a wide range of materials and coatings designed to meet specific performance criteria. It is important to select a material and/or coating that is suitable for the intended application and environment based upon factors such as corrosion resistance and mechanical properties of the material. For more information on selecting connectors, anchors and fasteners based upon corrosion resistance, please see Corrosion Information for Connectors and Fasteners, and Corrosion Information for Anchoring Products.

Corrosion and Wood

Corrosion and Concrete

Corrosion Resistance Recommendations and Classifications

If the treatment chemical information is incomplete, Simpson Strong-Tie recommends the use of a 300 series stainless steel product. Also if the treatment chemical is not shown in the Corrosion Classification Table, then Simpson Strong-Tie has not evaluated it and cannot make any recommendations other than the use of coatings and materials in the Severe category. Manufacturers may independently provide test results of other product information; Simpson Strong-Tie expresses no opinion regarding such information.

| Minimum Corrosion Resistance Recommendations | |||

|---|---|---|---|

| Low | Medium | High | Severe |

| FASTENERS & ANCHORS | |||

| Phosphate (gray, black), Clear (bright) zinc (ASTM F1941), Heavy electro-galvanized (ASTM A641-Class 1), Yellow zinc (ASTM F1941), Electrocoat (E-coat), Type 410 stainless steel |

Mechanically galvanized (AS 3566.2-C3, N2000, ASTM B695-Class 55), Quik Guard® coating, Hot-dip galvanized (ASTM A153-Class D), Double-barrier coating, Type 410 stainless steel with protective top coat |

Type 304 stainless steel, Type 305 stainless steel |

Type 316 stainless steel, Hot-dip galvanized (ASTM A153-Class C), Silicon bronze, Copper |

| CONNECTORS | |||

| Simpson Strong-Tie gray paint Powder coating Standard G90 zinc coating | ZMAX® (G185) Hot-dip galvanized (ASTM A123) | Type 316L stainless steel | Type 316L stainless steel |

| Corrosion Resistance Classifications | |||||||

|---|---|---|---|---|---|---|---|

| Environment | Material to be Fastened | ||||||

| Untreated Wood or Other Material |

Preservative-treated Wood | FRT Wood | |||||

| SBX-DOT Zinc Borate | Chemical Retention ≤ AWPA, UC4A |

Chemical Retention > AWPA, UC4A |

ACZA | Other or Uncertain | |||

| Dry Service | Low | Low | Low | High | Med | High | Med |

| Wet Service | Med | N/A | Med | High | High | High | High |

| Elevated Service | High | N/A | Severe | Severe | High | Severe | N/A |

| Uncertain | High | High | High | Severe | High | Severe | Severe |

| Ocean/Water Front | Severe | N/A | Severe | Severe | Severe | Severe | N/A |

|

|||||||

Structural Connections

Unmatched Quality from the Truss to the Foundation

With nearly 60 years of field and R&D experience, Simpson Strong-Tie® timber connectors are manufactured to the industry's highest standards. From framing angles to straps to heavy-duty joist hangers, we offer the most diverse product line so that you have the right product for the job.

Simpson Strong-Tie® connectors offer unmatched quality with laboratory and field testing, and are backed by our uncompromising commitment to customer service. As the company that built the connector industry, you can count on Simpson Strong-Tie® to work closely with builders, engineers and building officials to deliver innovative, building code-compliant solutions to help build safer, stronger structures economically. Download the Structural Connectors Overview Flyer.

Timber Connectors

From testing to service to availability, everything we do is engineered to ensure your project's success. With every product, you know you are getting the quality, value, service and on-time delivery that we have built our reputation on for the past 60 years.

From straps and ties to joist hangers and much more, Simpson Strong-Tie® structural connectors increase the strength and safety of timber-frame structures. Each connector is unique to Simpson Strong-Tie and is designed for specific applications without the need to adapt metal plating to suit a connection.

Steel Frame Connectors

From fully tested and engineered connectors and clips Simpson Strong-Tie® provides comprehensive structural solutions for cold-formed steel construction. From steel-to-steel connections to full-scale lateral solutions and curtain wall connectors, we remain committed to developing new technology that helps to advance the cold-formed steel industry.

Find out how Simpson Strong-Tie timber connectors can help you build the right way every day. Download the Cold-Fromed Steel Construction Connectors Catalogue.